IoT based asset tracking systems are commonplace in many high end warehousing and distribution facilities. The idea of being able to quickly see the location of equipment and high value assets is very appealing to management. But what about the staff that actually use the equipment or need to move the assets that are being monitored?

Scanning a QR code at its last location is great for knowing its last location. What if someone forgets to scan the QR code and moves the asset or equipment? What if I need a piece of equipment urgently and is not in its last known location from 15 minutes ago? What about reporting the condition of equipment or tracking usage to trigger preventative maintenance alerts?

Asset tracking systems also need to be linked to the people that use the equipment most – frontline staff. Data on the move is key to keep staff and processes efficient. Staff being able to see quickly where something is on a wearable or handheld work device allows them to carry on with their task without going back on themselves. Staff could also potentially use these devices to provide feedback on the condition of equipment and assets.

The Power of Connected Data: Turning Insight into Action

It’s quite useless to have a standalone asset tracking system that doesn’t provide insights in real time. It’s reactive, it’s slow, and the tracking system will become more of a burden for your IT team than a useful tool for frontline workers.

You might think that updating that asset tracking system to provide real-time insights would make it a useful tool, but I wouldn’t necessarily agree. Yes, real time insights do have their benefits, but they only really become effective when the real time insights provided can be actioned quickly, and effectively, usually by an actual human. To do this, the asset tracking system must be linked with other systems which the company uses, such as a communication platform to notify someone or a create a task that requires immediate attention

Here’s an example: Let’s say a delivery company are using an asset tracking system to alert when pallet trolleys are moved outside the loading zone, which has been geofenced. This tracking system is only useful if the asset alert arrives in real time, and absolutely no use, if the pallet trolley left the zone and is in the back of a lorry which is now half an hour away. The only way to act on the alert, is if the frontline workers have access to the alert, which must be specific, and provided in real time. If the frontline workers had access to Sense Badges, they might see an alert which reads “Pallet Trolley 1 has left zone, retrieve immediately”. This allows the worker to collect the trolley before realising they’re now stuck without one and are unable to load large or heavy items until the trolley returns.

Hopefully, the point of my story is clear – connecting backend systems to frontline workers, in real time, saved the company time and money by preventing a block in the workflow from occurring.

Connecting Asset Tracking to Maintenance Workflows: Improving Asset Uptime

Thinking about the example I just gave about the pallet trolley, you could apply the same principles (asset tags, geofences, and alerts) to several scenarios to suit several purposes. One such purpose is the maintenance of equipment. Connecting asset tracking data to maintenance workflows can improve asset uptime. Using a standalone system to report on asset status lacks the ability to trigger maintenance actions, which could be the difference between minutes of downtime, or hours.

In a factory, a machine part might need replacing quickly, by a specialist. Finding the part you need, and the nearest available specialist can be streamlined by pairing asset location data with frontline work communication. Workers on the machine line can request help from the nearest available engineer who in turn can find the nearest part that they need.

Another approach would include using machine sensors, which could automatically trigger an alert directly to the engineer, stating the exact part that is needed, and where to find it. Using a standalone to diagnose problems, without connecting to a human who can fix the problem promptly can lead to unnecessary downtime and decreased productivity.

Connecting Asset Tracking to Security Systems: Enhancing Asset Protection

Securing valuable assets is paramount to the continuity plans of many businesses, connecting asset tracking to security systems can help to enhance the level of protection that assets are provided with.

Standalone asset tracking systems do provide location information but fail to trigger security alerts. However, linking asset tracking to an end-to-end system that communicates with security guards as well as security systems can trigger alerts and provide useful information about the situation that a security guard is about to encounter.

Something as simple as moving the asset could trigger a security system, alerting security to which asset(s) has been moved, and where it is moving. Such a system gives security enforcement have the upper hand in preventing the asset from leaving the site and recovering it as soon as possible.

Connecting Asset Tracking to Workforce Management Systems: Increasing Workforce Productivity

Connecting your RTLS to other systems has many other uses and benefits, alongside improving asset protection and increasing asset uptime. Linking your asset tracking to workforce management systems can enhance productivity, too.

Standalone systems can tell you where a piece of equipment is, but that information then needs to be communicated separately to anyone looking to schedule maintenance or assign tasks. With an integrated system like Sense, workforce management can use the location information to assign tasks as they occur to nearby workers, they can also schedule maintenance on equipment when it’s out of use. Enabling workforce management to assign tasks based on location and availability of employees and equipment improves productivity by cutting prolonged journeys, reducing time wasted searching for (or waiting for) equipment.

For example, a construction company can use the connection of asset tracking with workforce management to keep tools and equipment functioning, by assigning the nearest technician to repair a piece of equipment marked for maintenance, or reassign an employee needed to operate a piece of machinery, such as a digger, at short notice. This helps to keep progress ongoing, without unnecessary downtime, or interruptions to the necessary order of tasks.

Connecting Asset Tracking to Budget Planning: Improving Financial Management

The uses of asset tracking data don’t stop here. There are also budgeting benefits to be had. Asset usage is difficult to monitor, and it’s even more difficult to figure out how spending should be allocated based upon that asset usage. Standalone asset tracking systems report on asset usage but lack the ability to inform budget planning decisions.

By connecting the systems which track asset usage with budget planners, financial management is made easier. Operations teams can plan to have enough equipment available or downsize if they already have too much. Those same teams can move equipment if it’s being used most in an area far away from where it’s stored – helping with productivity. If an asset often requires repairs, budget planners can take advantage of bulk buying spare parts in advance to make the most of economies of scale.

Assets should also have profiles that tell you how often they should be maintained based on either a period of time or number of uses to help you plan budget spend for maintenance. Now you could use the date to create alerts that equipment needs maintenance, or the number of times the equipment has been used can trigger a task creation for engineering to carry out maintenance when it is 90% of its lifetime. If you used this metric, you could work out how often in a fiscal year the usage cycle is completed, for example, if you have equipment that needs to be maintained every 100 uses and you use it 200 times in a year, you know to budget for two sets of maintenance.

Here’s an example. An organisation uses asset tracking to understand what equipment is being used, frequency, and where. This allows the management team to understand what equipment is used the most and least, and availability of all equipment. For budget planning, management can see what equipment has the least availability and used the most to assign budget to buy more. The system can also use data to see how many times equipment has been used, and which pieces of equipment are approaching maintenance anniversaries – this data allows better maintenance budget planning.

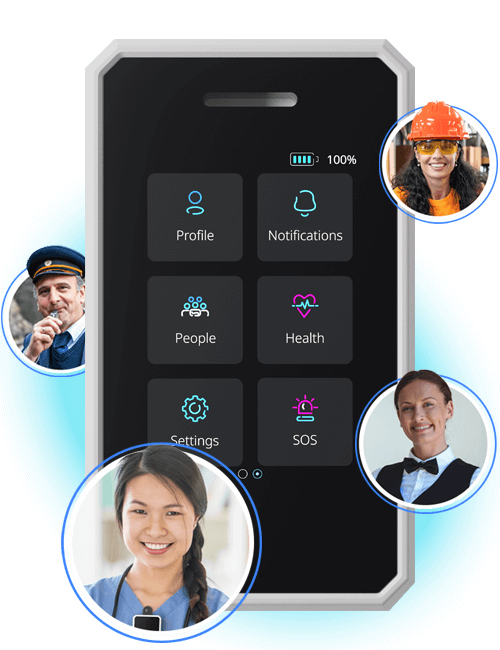

The Future of Asset Management: Introducing Sense Wearable Solution

Sense is a wearable solution for frontline workers, it connects asset tracking, management, and frontline workers altogether in real time. The Sense system is configurable to suit different locations, industries, uses, and budgets. Sense Badges are worn by frontline workers, these relay information such as location, alerts, or direct messages. Tags are placed on assets; these can report location in real time and track movements. Tags and Sense badges communicate with Sense Gateways, which act as relays to the Sense Console, software which allows all the data collected to be analysed and interpreted by workforce management, before sending communications back to Sense badges to assign tasks.

The Sense platform can take all the data collected from movements, the number of reservations, check outs and users to create real actionable insights such as showing the most used equipment, where equipment is used most, and how many times each equipment has been checked out, indicating a use, thus helping track maintenance cycles. Automated workflows can wait for a trigger such as 90% use limit has been met and therefore create a task for the maintenance team to schedule preventative maintenance.

All this data can help with better budget planning by showing what equipment is needed and how often equipment is being maintained. With better budget maintenance and the ability to show ROI on equipment usage, organisations can better plan their assets and spend more effectively and efficiently.

Conclusion

Companies using connected asset tracking systems, like Sense, can benefit from turning insights into actions. This improves asset uptime, enhances asset protection, increases workforce productivity, and improves financial management. You might want to consider whether you should have a more automated asset tracking system that automates the administrative side of asset management, provides real actionable data points, as well as be connecting your workflows for a more efficient working environment. If you do want to check out how Sense can improve your asset tracking, contact us today to speak to our experts.